What is an RTD sensor or a Pt100?

RTD stands for Resistance Temperature Detector. This is a form of temperature measurement using resistance. An RTD contains a (platinum) resistor that changes its resistance value as its temperature changes. After calculating the resistance, one could determine the temperature.

At its core, RTDs use a specific type of metal (in most cases platinum, but also nickel and copper are used) that, depending on the resistance measured in that metal, can determine the temperature. The actual measurement occurs at the element. An RTD works based on the correlation between metal temperature and resistance.

When a temperature of metal increases, the metal resistance to the flow of electricity increases as well. This occurs because as the atoms and molecules of the metal are starting to move, it is more difficult for the free electrons to move through the material without colliding. So, based on the resistance that is measured in a certain type of metal, one could determine what the temperature is.

The relationship between resistance and temperature is relatively linear, resulting in Pt100 sensors to be extremely accurate for a certain set temperature. Temperature ranges vary from -200 to + 850°C depending on the sensor and the class.

An RTD device used to measure temperature is a Pt100 sensor, also called RTD or thin film sensor. Pt100 sensors have a resistance of 100 Ohms at 0 °C. The platinum sensor changes its resistance value when temperature changes.

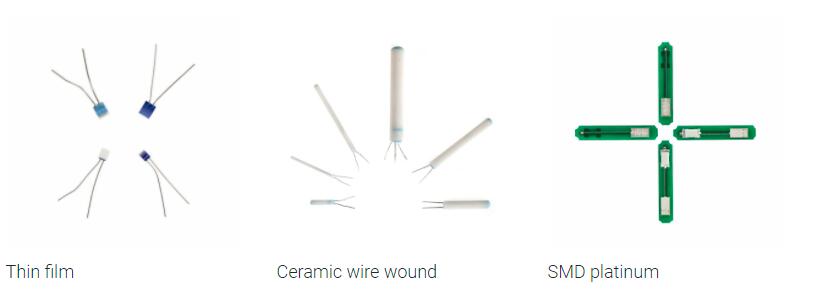

Type of RTD elements

There are several types of RTD elements. The most common two are thin-film platinum elements and wire wound platinum elements. These elements are most used by our customers. RTD sensors most often contain platinum, which has a near linear resistance versus temperature gradient.

A thin film RTD element is constructed by placing a sensing layer of platinum on a ceramic substrate, covered with passivation glass layers. This protects the Pt sensor element from environmental influences.

A ceramic wire wound element is a sensor in which a platinum wire is wound into a small coil which is inserted into the holes of a high purity alumina tube.

One other commonly used RTD sensor is an SMD sensor. This is a sensor that is specifically designed to fit on PCBs.

Kamet offers three types of Pt100 elements: thin film, ceramic wire wound & SMD sensors. Also Pt500 or Pt1000 RTD sensors are used. These RTD sensors have Ohm values of 500 and 1000 Ohms respectively at 0°C.

What is the difference between a platinum and nickel resistor?

Platinum RTD sensors are most often used because platinum has a near linear resistance versus temperature gradient. But also nickel resistors are available.

Platinum resistors have practically taken over as a resistance material in industrial measurement.

The biggest advantage brought by these resistors is their high chemical resistance and the fact that the material is relatively easy workable. Platinum is also wildly available in highly refined form.

The interchangeability of the platinum temperature sensors is unmatched by other temperature sensors. This is due to the properties of a platinum temperature sensor which are specified in the European standard EN 60 751.

Nickel resistors are also commonly used asresistance material. The price advantage compared to platinum is significant. However the measurement range of a nickel temperature sensor is limited from -60°C to +250°C. The characteristics of these nickel sensors are laid down in DIN 43 760 (no longer valid) and the characteristics are also usually specified by the manufacturer.